Kirloskar Brothers Limited (KBL), a world leader in providing fluid management solutions, successfully received a patent for its Concrete Volute Pumping Assembly.

This patent is a significant milestone as it will help the company offer its Concrete Volute Pumps with reduced submergence leading to reduced excavation cost to the customer. The patent will further consolidate KBL as a leader in the designing and manufacturing of Concrete Volute Pumps worldwide.

KBL has designed and constructed CVPs for many large irrigation and powers projects, stormwater applications, including Sardar Sarovar Narmada Nigam Ltd, Reliance Energy Ltd, National Thermal Power Corporation (NTPC), Nuclear Power Corporation of India (NPCIL), BMA Thailand.

READ: Wilo, Industrial Leaders creates shared-source software for industrial automation

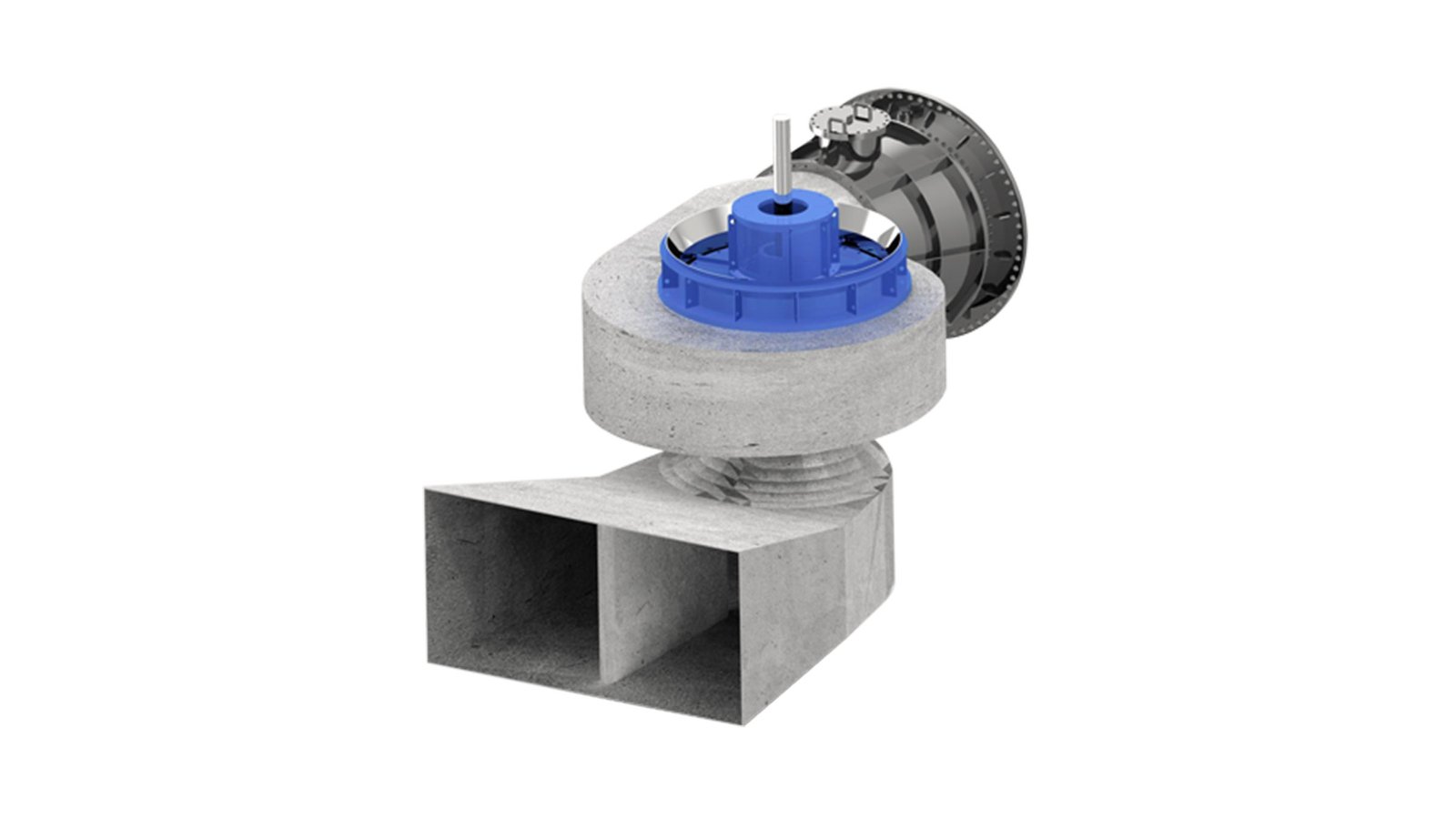

The Concrete Volute Pump was a revolutionary development in the pump industry. Concrete Volute Pumps derive their name as the casting & suction draft tube is concrete, while the rotating parts are metallic. As the casing is constructed in concrete at the site, CVP is the most suitable pumping option from techno-economic consideration for handling large volumes of water. Concrete Volute Pumps guarantee strength and rigidity and virtually eliminate the problems of corrosion and erosion. It also ensures higher & consistent pump efficiencies over a sustained period of operation. Due to the simplicity of construction and ease of maintenance, the reliability achieved is 99.95%.

Concrete Volute Pumps by Kirloskar are widely used for Sea Water applications, applications like Circulating / Condenser Cooling Water for Power Plants, Lift Irrigation, Water Supply, Drainage and Flood Control, Dry Docks and Desalination. High Reliability, Design Simplicity and Superior Operating Performance make Kirloskar Concrete Volute Pumps a trusted choice.

About Kirloskar Brothers Ltd (KBL)

KBL was established as Kirloskar Brothers in 1888, from which various group companies emerged later. Kirloskar Brothers Limited was incorporated as a limited liability company on January 15, 1920. A global conglomerate, it provides complete fluid management solutions for large infrastructure projects in the areas of water supply, power plants, building & construction, process industries, irrigation, oil & gas, and marine & defence. It engineers and manufactures industrial, agricultural, and domestic pumps, valves, and hydro turbines. It is also India’s largest centrifugal pump manufacturer with eight manufacturing facilities in India along with other international subsidiaries and operations in the Netherlands, South Africa, Thailand, the United Kingdom, and the United States of America. KBL has over 12,000 channel partners in India and 80 overseas and is supported by the best-in-class PAN-India network of authorised service and refurbishment centres.

All manufacturing plants of KBL have the necessary Quality, Environment, Occupational Health & Safety, and Energy standard certifications under the Integrated Management System (ISO 9001:2015, ISO 14001:2015, ISO 45001:2018, and ISO 50001:2018). The company’s Kirloskarvadi plant is a state-of-the-art integrated manufacturing facility, which houses Asia’s largest hydraulic research centre with a testing facility of up to 5000 kW and 50,000 m3/hr. KBL is the only pump manufacturing company in India and the 9th in the world to be accredited with the N and NPT certification by the American Society of Mechanical Engineers (ASME).