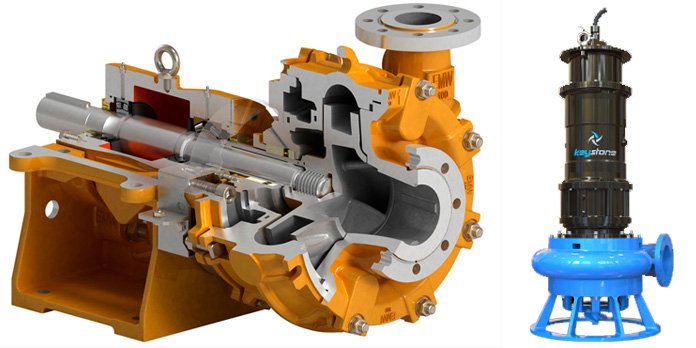

A Slurry pump is a special type of pump able to handle slurry. Unlike water pumps, slurry pumps are subject to wear. They are also more robust and heavy duty. As such, it is advisable to keep and follow through with maintenance as well as repairs for the slurry pump.

Seals-what most people are unaware of- whether packing or a mechanical seal, are one of the constituents that are usually replaced in a slurry pump. This is because abrasive particles can easily wear through packing or clog the mechanical seal components. This, in turn, tends to reduce the seal life down to weeks or even days in worst case scenarios.

As such, it is best to be aware of some of the best practices that speed up packing as well as seal replacement when necessary.

Also Read: Avoid catastrophic slurry pump cavitation

Lantern rings

For instance during packing, you should ensure you avoid the common lantern ring issues. This is caused by removing the lantern rings, which will result in their clogging. Once clogged, removal of the lantern rings becomes very hard.

On the other hand, most people tend to leave the lantern rings in place so as to avoid incurring such issues. This unfortunately leads to erosion and extrusion of the bottom rings. This, in turn, forces the lantern ring down to the stuffing box, misaligning it with the lantern ring port.

The general alteration will prevent the flush from going down the shaft and into the pump casing. As a result, solids are able to penetrate under the packing and this results in a shorter life of the same. One characteristic of a misaligned lantern ring is heavy flush water leakage on the OD of the packing.

Alternatively, you could avoid the aforementioned challenges by avoiding lantern rings altogether. This is because research has proven that the first three rings of packing do the majority of the sealing while the bottom rings help keep solids out.

With this knowledge, you can be able to use a throat bushing that has built-in flush ports. This not only eliminates the need to remove the lantern ring during repacking but it also ensures you use less packing.

Furthermore, since the top rings do most of the sealing, sealing capability will not be compromised. Moreover, specifically engineered bushings are available. These help to alter the flow of water within the stuffing box to remove solids.

Alternatively, a bushing is best for limiting the amount of particulate that can permeate the seal chamber. As such, there are engineered bushings designed to remove particulate from the seal chamber. They also help the seal operate in a clean.

Other methods that help prolong slurry pump life as well as reduce maintenance include the use of reinforced coatings, which are also known to reduce equipment costs. Furthermore, proper and automated lubrication extends bearing life. It is also important to note that for easier disassembly of the slurry pump, you should use high quality bolt and nut lubrication.