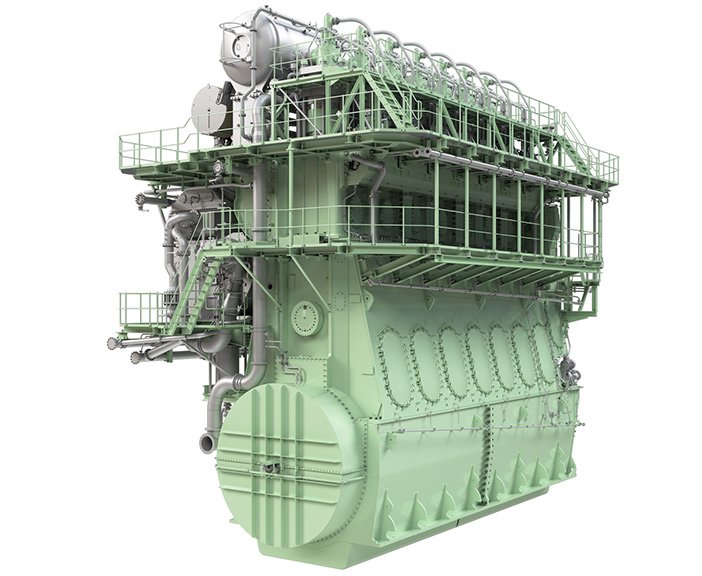

The MAN B&W 14K98ME-C engine stands as one of the most astonishing achievements in modern engineering. Imagine a mechanical heart so powerful that its total output rivals a small power station. Its scale is breathtaking. Its components are measured in meters. Its weight is counted in thousands of tonnes. Yet this machine operates not in power plants, but deep inside the hulls of the world’s largest container ships.

- A Monument to Scale and Precision

- Thermodynamic Brilliance: Efficiency as the New Battleground

- 1. Two-Stroke Diesel Cycle

- 2. Electronic Common Rail Injection

- 3. Waste Heat Recovery Systems

- 4. Advanced Turbocharging & Air Management

- Digital Intelligence Meets Mechanical Muscle

- The Engine as Economic Infra structure

- Sustainability, IMO Regulation & Future Fuels

- Africa’s Maritime Positioning

- The Future: Beyond 50% Thermal Efficiency?

With a staggering output of 84.42 Megawatts (113,210 horsepower), the MAN B&W 14K98ME-C engine powers maritime giants that stretch nearly 400 meters in length, transporting up to 24,000 TEUs of goods per voyage. These voyages form the backbone of the global supply chain, connecting continents and sustaining international commerce.

Maritime trade is the silent infrastructure of globalization. Over 90% of world goods move across oceans. Without engines like the 14K98ME-C, the entire shipping economy would collapse.

A Monument to Scale and Precision

The scale of the engine itself is nearly incomprehensible. Standing over 17 meters tall, stretching almost 28 meters long, and weighing roughly 2,600 tonnes, it exceeds the mass of 200 city buses. Inside its massive cylinder block sit fourteen cylinders, each with a bore diameter of 98 centimeters. That number is not a typo. Each cylinder is nearly one meter wide.

These cylinders fire in sequence, generating a relentless rotational force that drives a single propeller—sometimes 10 meters in diameter—to speeds exceeding 70 revolutions per minute. That propeller, in turn, pushes a quarter-million-tonne vessel across dense seawater at speeds beyond 22 knots. Even at such speeds, the propeller must maintain smooth hydrodynamics to avoid cavitation and vibration, problems that could undermine long-term structural integrity.

This is engineering dominance executed at planetary scale.

Thermodynamic Brilliance: Efficiency as the New Battleground

Power alone no longer defines maritime propulsion. Fuel costs for ultra-large container vessels can exceed tens of millions of dollars per year. Meanwhile, global regulations demand lower emissions. Efficiency has become the new battleground, and it is here that the MAN B&W 14K98ME-C engine shines.

It achieves a thermal efficiency of nearly 50%, placing it among the most efficient combustion engines ever built. For comparison, typical automotive gasoline engines operate between 25%–30% thermal efficiency, while commercial jet turbines average around 40%–45% in cruise conditions.

This leap in efficiency is not accidental. It is the result of decades of incremental innovation and intelligent adaptation across four major technology pillars:

1. Two-Stroke Diesel Cycle

The engine operates on a two-stroke marine diesel cycle, where each downward motion of the piston produces power. This delivers higher torque at low RPM, ideal for massive propeller drive systems. Two-stroke operation also enables efficient combustion of heavy fuel oil (HFO), which, despite environmental criticism, remains the dominant fuel for long-haul cargo carriers.

2. Electronic Common Rail Injection

The “ME” in MAN B&W 14K98ME-C engine stands for electronically controlled. The “C” designates its common rail fuel injection architecture. Instead of relying on cam-driven systems, the engine uses high-pressure electronic injection that optimizes combustion timing under varying load conditions. The result is cleaner combustion, reduced fuel consumption, and lower wear.

3. Waste Heat Recovery Systems

Maritime engines produce immense thermal energy. Rather than venting that heat, modern vessels capture it to generate steam, drive turbines, and power onboard electrical systems. Waste heat recovery alone can yield 5%–10% additional efficiency, improving ship-wide fuel economics and lowering emissions per container moved.

4. Advanced Turbocharging & Air Management

Multiple turbochargers force enormous amounts of air into the cylinders at high pressure, ensuring clean and complete combustion. Some vessels implement two-stage turbocharging, boosting overall power density and further improving fuel burn efficiency.

Digital Intelligence Meets Mechanical Muscle

While the 14K98ME-C engine appears mechanically ancient in form, it is digitally sophisticated at its core. Thousands of sensors feed real-time data into its electronic control system, adjusting combustion parameters to match sea state, weather, and operational demand. This dynamic optimization improves:

✔ Fuel consumption

✔ Cylinder balance

✔ Valve timing

✔ Emissions

✔ Component longevity

It can even support slow steaming, a strategy introduced during recessionary periods to lower operating costs. By cruising at slower speeds (e.g., 18 knots instead of 22), shipping lines can reduce fuel consumption by up to 30%. For vessels crossing Asia–Europe and Africa–Asia corridors, that equates to millions in annual savings.

The Engine as Economic Infra structure

Why does the world need such a colossal machine? The answer is rooted in the economics of scale. One HMM Algeciras-Class vessel can carry 24,000 TEUs—the equivalent of roughly 24,000 loaded trucks. Moving that cargo via air freight would be economically impossible and environmentally catastrophic.

Ultra-large container vessels (ULCVs) dramatically lower cost-per-container by spreading fuel costs across thousands of units. This cost model underpins modern globalization, from electronics and textiles to vehicles and food products. Without engines like the MAN B&W 14K98ME-C engine, African ports such as Mombasa, Durban, Lagos, and Tanger-Med could not efficiently integrate into global trade corridors.

Sustainability, IMO Regulation & Future Fuels

Efficiency alone does not solve shipping’s environmental challenges. The sector contributes roughly 3% of global emissions. The IMO 2020 regulation reduced sulfur limits in marine fuel and ushered in widespread adoption of scrubbers, low-sulfur fuels, and LNG-powered ships.

The next frontier is decarbonization. MAN Energy Solutions has been developing methanol (ME-LGIM), LNG (ME-GI), and ammonia-capable (ME-LGIA) engines. Future hybrid propulsion chains may integrate:

✔ Fuel cells

✔ Carbon-neutral fuels

✔ Battery-assisted systems

✔ Wind-assist rotors

These innovations aim to maintain shipping competitiveness while reducing carbon intensity.

Africa’s Maritime Positioning

Africa sits at the crossroads of East–West and North–South shipping lanes. Ports like Durban, Djibouti, Mombasa, and Tanger-Med are modernizing to handle ULCV-class vessels. Improved maritime infrastructure unlocks:

✔ lower trade costs

✔ stronger export competitiveness

✔ faster logistics cycles

✔ improved supply chain integration

The importance of marine propulsion technology extends beyond engineering—it influences economic development across the African continent.

The Future: Beyond 50% Thermal Efficiency?

As engineers pursue higher thermal efficiency, thermodynamic ceilings become the limiting factor. Yet maritime propulsion has consistently broken perceived limits. With digital optimization, waste heat recovery, and hybridization, a future engine surpassing 50%+ efficiency is no longer a fantasy.

That future may run on ammonia, methanol, hydrogen, or fuels not yet common in global shipping. However, the economic logic remains unchanged. The world needs to move enormous volumes of cargo at the lowest possible cost with the smallest environmental footprint.

What makes the MAN B&W 14K98ME-C engine unique?

Its unmatched power output, high thermal efficiency, and digital fuel management system set it apart.

Why do container ships need so much power?

To push vessels exceeding 250,000 tonnes through seawater at commercially viable speeds.

Is slow steaming still used today?

Yes. It reduces fuel consumption, emissions, and maintenance costs on long global routes.

Will future maritime engines move away from fossil fuels?

Yes. Methanol, ammonia, LNG, and hybrid systems are rapidly emerging in commercial fleets.

Could next-generation engines push maritime efficiency beyond 50% while decarbonizing global trade? The coming decade will reveal whether propulsion innovation can meet both economic and environmental demands.

Share